5C Pull-Back Collet Block Pneumatic OR Hydraulic (65203-H)

In Stock

Your Price:

$1,103.00 USD / Each

*The product image(s) shown represents a range of the product and is for illustration purposes only. This may not be an exact representation of the product.

*The product image(s) shown represents a range of the product and is for illustration purposes only. This may not be an exact representation of the product.

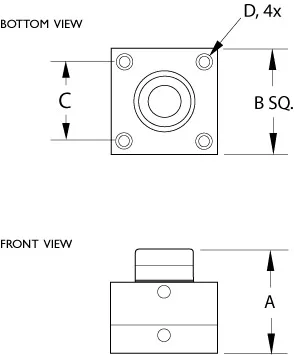

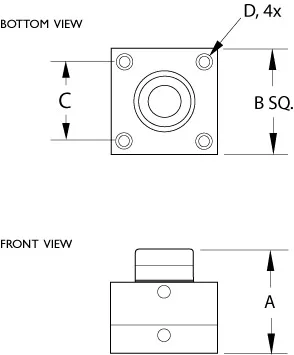

| A | 3.90" (99.18mm) |

| B | 4.00" (101.60mm) |

| C | 3.00" (76.20mm) |

| D | 3/8-24 SHCS |

| E | 2.875" (73.02mm) |

| Collet Series | C |

| Actuation Style |

Pneumatic Hydraulic |

| Style | 5C |

This versatile 5C threaded-nose model uses standard 5C collets, expanding collets or step chucks to accommodate parts up to 6" (152.4mm) in diameter. This heavyduty steel unit is designed for use with pneumatic service to 250 PSI or hydraulic service to 750 PSI. Draw tube force is 7.5 times the line pressure which maximizes the gripping force available from this compact unit. Combine units for multiple part setups. Connector bushings will eliminate the external plumbing between units.

Application

This 5C collet closer is a stationary unit with a double-acting cylinder. It is effective on machine and assembly operations that require reliable clamping and unclamping. Use the collet block as a single unit or mount multiple closers on rotary tables, pallets, fixtures or tombstones for increased productivity.

Specifications

- Maximum unit operating pressure – 250 psi air, 750 psi hydraulic (17 bar air, 51 bar hydraulic)

- Draw tube force – 7.5 x line pressure

- Collet capacity – 5C {1/64" to 11/16" (.39 to 26.98mm) round}, 5C Step chuck up to 6" (152.4mm)

- Thru-hole in base

- Four 3/8-24 mounting holes in bottom of base

- Two 3/8" (9.52mm) dowel holes in bottom of base

- Two 1/4" NPT ports

- 2-position, 4-way control valve recommended for hydraulic operation, 2-position, 3-way control valve recommended for pneumatic operation (not included)

Safety

- Do not over tighten the mounting hardware or the plumbing fittings.

- When installing a collet in the closer, do not over tighten the collet.

- Do not exceed maximum operating pressure of 250 psi air or 400 psi hydraulic (17 bar air, 27 bar hydraulic).

- Make sure that the collet retains your material when the collet is closed.

Installation

1. Mount the collet block to a rigid flat surface.

2. Plumb your first supply line using 5000 psi (344 bar) rated steel tubing to the CLAMP 1/4 NPTF port of the collet block and the normally OPEN 1/4 NPTF port of your control valve.

3. Plumb your second supply line using 5000 psi (344 bar) rated steel tubing to the UNCLAMP 1/4 NPTF port of the collet block and the normally CLOSED 1/4 NPTF port of your control valve.

4. Plumb your control supply to the 1/4 NPTF pressure port of the valve.

5. This configuration maintains a closed collet until the valve is actuated.

Operation

1. Remove the supply from the valve.

2. Loosen the collet locking screw until the tip does not protrude into the piston guide threads.

3. Put a witness mark on the face of your collet in-line with the collet groove and then insert the collet in the top of the collet closer.

4. Using the collet wrench, turn the collet clockwise until it contacts the piston taper.

5. Turn the collet counter clockwise until the collet witness mark lines up with the locking screw.

6. Tighten the collet locking screw. Do not overtighten.

7. To close the collet closer, insert a workpiece in the collet, and connect the pneumatic supply to the control valve. WARNING: Do not close the closer without the workpiece in the collet.

8. Regulate your supply pressure to a level that assures effective workholding only. Continuously operating the closer at maximum pressure will decrease the service life of the seals and collet. WARNING: Pressure to this closer above 250 psi air or 400 psi hydraulic (17 bar air, 27 bar hydraulic) may overstress the 5C collet. Refer to the manufacturer's recommended drawbar force when using a step chuck or expanding collet.

9. To open the collet, actuate the valve.

Maintenance

If, over a period of time, you experience a decrease in clamping force even though pressure remains unchanged, remove the collet block from service, disassemble, and replace any damaged or worn o-rings.

WARNING: product can expose you to chemicals, such as lead, including one or more listed chemicals which are known to the State of California to cause cancer or birth defects or other reproductive harm.

For more information, go to www.P65Warnings.ca.gov