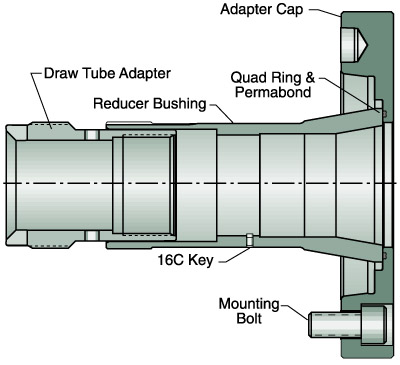

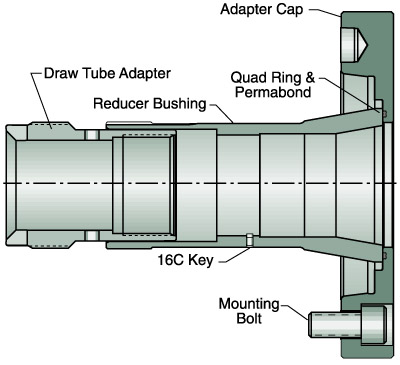

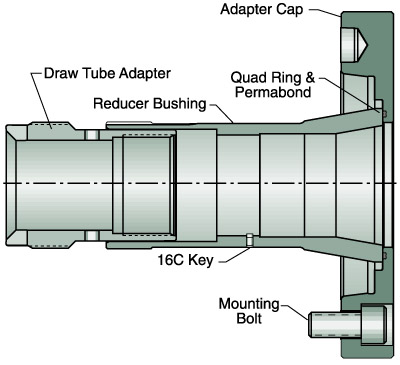

A2-6 Spindle 20C to 16C Spindle Collet Adapter Assembly

Your Price:

$1,676.00 USD / Each

*The product image(s) shown represents a range of the product and is for illustration purposes only. This may not be an exact representation of the product.

| Spindle Size | A2-6 |

| Collet Series | C |

| Style |

20C 16C |

Collet adapters let you use smaller collets in machines with larger collet seats. Units are available to adapt 5C collets to 16C spindles, 16C collets to 20C and 25C spindles and 16C step chucks to 20C spindles. These units are valuable when you do not have the proper size standard collet for the machine but do have the proper size in a smaller style collet. Do not consider this unit when doing precision work. Because of the number of parts in the assembly, the TIR of the machined diameters to the chucked diameters may be unacceptable. This system should not be considered when doing many collet changes a day. It may take from 15 to 30 minutes to change a collet. It is more cost effective to purchase the proper style collet for the machine tool.

Spindle Collet Adapter Parts Lists:

- 20C-16C Draw Tube Adapter 75410000000000

- 20C-16C Reducer Bushing 75370000000000

- (4) Bolts: MS 0104219

- 20C-16C Adapter Cap 75430000000000

- Quad Ring 41 001115145

- 16C Key 75390000000000

- Permabond 910: QC 0010884

Mounting Instructions for 20C-to-16C and 25C-to-16C Spindle Collet Adapters for Hardinge 20C and 25C Spindle Lathes

- Remove any collet or step chuck which may be in the lathe spindle.

- Remove any spindle-mounted device (step chuck closer, jaw chuck, expansion collet mount, face plate, etc.) which may be on the machine.

- Thoroughly clean inside the spindle, as well as the spindle mount locating surfaces, to remove all chips, grit and coolant. Use a lint-free cloth to insure the surfaces are completely free of lint.

- Use Die Maker's Grease and coat all surfaces.

- Remove the draw tube from the spindle of the lathe. (Refer to the Operator's Manual for your lathe to obtain instructions for this procedure.)

- Clean the threads in the draw tube and on the Draw Tube Adapter. Coat the threads with Die Maker's Grease.

- Put the draw tube in a vise with soft or copper jaws. Grip the tube just behind the collet threads.

- Firmly tighten the Draw Tube Adapter into the machine draw tube using a spanner wrench or a piece of 1/4" round stock.

- Replace the draw tube in the lathe per the instructions in the Operator's Manual.

- Actuate the collet closer to its full forward position.

- Insert the Reducer Bushing into the spindle. This bushing slides over the Draw Tube Adapter inside the spindle.

- Mount the Adapter Cap on the spindle, orienting as shown on the face of the cap. Tighten the four mounting Bolts.

- Insert the 16C collet & turn the draw tube to catch the collet threads. Adjust the collet using the methods outlined in the lathe Operator's Manual.

NOTE: Do not Exceed 7,000 Lbs. draw force.

WARNING: product can expose you to chemicals, such as lead, including one or more listed chemicals which are known to the State of California to cause cancer or birth defects or other reproductive harm.

For more information, go to www.P65Warnings.ca.gov